What Is Molybdenum Bar?

As a representative product of refractory metal molybdenum, molybdenum bar is a rod-shaped product with high-purity molybdenum as the main material. It is often called molybdenum rod or molybdenum rod in the industrial field. The purity of molybdenum bar is as high as 99.7%. Due to its thermal, mechanical, chemical and electrical properties, it has become the core basic material of many industries such as smelting and power equipment.

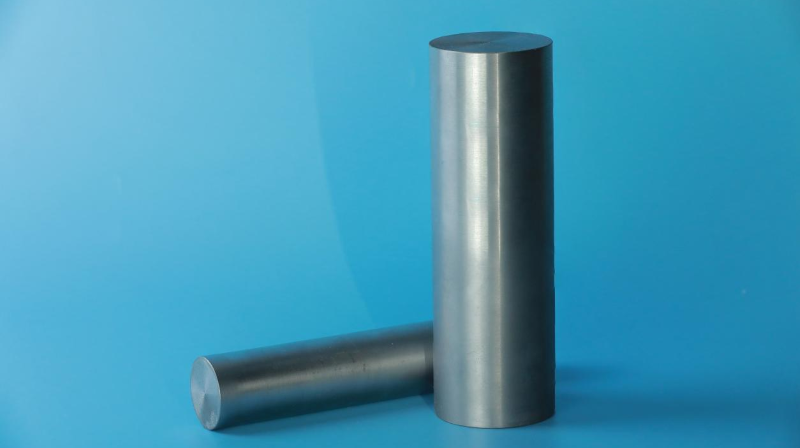

Molybdenum bar inherits many excellent properties of metal molybdenum. The surface presents a bright silver metallic luster in its natural state. If it is treated by special processes and a lubricant or an oxidized coating is attached to the surface, it will present a black appearance. Molybdenum bar has a high melting point and specific gravity, which gives it morphological stability and high-strength bearing capacity in high temperature environments. At the same time, molybdenum bar has excellent mechanical properties, and its high strength and high hardness enable it to withstand complex mechanical stresses; the low thermal expansion coefficient ensures that the dimensional accuracy is maintained when the temperature changes drastically, effectively avoiding structural failure caused by thermal deformation. In terms of electrical and thermal conductivity, molybdenum bar also has outstanding performance. It can not only conduct current efficiently, but also dissipate heat quickly. It is suitable for equipment with strict thermal management requirements. In addition, molybdenum bar has good chemical stability and strong corrosion resistance in conventional environments, which provides guarantee for long-term use under various working conditions.

The preparation of molybdenum bar requires multiple rigorous and complex processes: Raw material pretreatment: molybdenum concentrate is used as the starting material and converted into roasted sand by oxidative roasting. This process oxidizes molybdenum sulfide into oxides for subsequent processing. Leaching and purification: roasted sand is mixed with ammonia water for leaching to generate ammonium molybdate solution; after purification treatment to remove impurities, hydrochloric acid is added for neutralization and crystallization to obtain ammonium polymolybdate. Subsequently, ammonium polymolybdate is dissolved to form ammonium molybdate solution again, and ammonium paramolybdate is obtained by evaporation and crystallization. Calcination and reduction: ammonium paramolybdate is calcined to generate molybdenum trioxide, which is then reduced with hydrogen to obtain high-purity molybdenum powder. Molding and sintering: After the molybdenum powder is pressed and molded, it is sintered at high temperature to finally form a dense molybdenum bar product.

In terms of appearance and shape, molybdenum bar can be divided into rectangular molybdenum bar and cylindrical molybdenum bar; in terms of surface state, molybdenum bar can be divided into alkali-washed molybdenum bar, polished molybdenum bar, lathe molybdenum bar and polished molybdenum bar; in terms of use, molybdenum bar can be divided into conventional molybdenum bar, high-temperature molybdenum bar and steelmaking molybdenum bar.

Rectangular molybdenum bar: suitable for scenes requiring large-area contact or special structural assembly, such as some industrial mold manufacturing. Cylindrical molybdenum bar: the most common form, widely used in mechanical processing, electrode manufacturing and other fields, convenient for subsequent processing such as turning and drilling.

Alkaline washing molybdenum bar: Place ordinary molybdenum bar in an alkali solution prepared by sodium hydroxide, sodium carbonate or trisodium phosphate for alkaline boiling and descaling. The surface of the treated molybdenum bar is smooth and presents a uniform gray metallic luster. It is often used in basic industrial applications with high requirements for surface cleanliness. Polishing molybdenum bar: Through multiple processes of rough grinding, medium grinding and fine grinding, the surface of the molybdenum bar reaches a high degree of finish, which is suitable for the manufacture of precision parts with strict precision requirements.

Lathe molybdenum bar: After lathe processing, the surface is flat but relatively rough, which is suitable for occasions where the surface finish requirements are not high and mechanical properties are more emphasized.

Polishing molybdenum bar: Mechanical, chemical or electrochemical polishing process is used to greatly reduce the surface roughness, making the surface of molybdenum bar as bright as a mirror. It is often used in electronic devices, high-end optical equipment and other fields with extremely high surface quality requirements.

Conventional molybdenum bar: Mainly used for the production of molybdenum wire. The molybdenum wire made by drawing process can be used in products such as electric light sources and electronic components. High temperature molybdenum bar: With its excellent performance in high temperature environment, it is often used to prepare high-strength wire cutting molybdenum wire, as well as to manufacture high-temperature electric heating components, electric light source materials and high-temperature structural parts, etc., to meet the special needs of high-temperature fields such as aerospace and metallurgy. Steelmaking molybdenum bar: As a steel additive, adding molybdenum bar in the steelmaking process can effectively improve the high-temperature strength, toughness and corrosion resistance of steel.

As a molybdenum product technology enterprise, we have selected advanced automation, process technology and environmental protection equipment, with good environmental governance effects, and at the same time have a domestic advanced laboratory testing center. In addition, we are mainly committed to the research and development and production of molybdenum deep processing products, and strive to form a deep processing industry chain integrating "ammonium molybdate-pure molybdenum trioxide-molybdenum powder". The factory is located at No. 52, Zhongxin Road, Taihe District, Jinzhou City, Liaoning Province, China. The factory covers an area of 66,700 square meters, and the first phase has a construction area of 28,500 square meters. Welcome to visit our factory at any time.