Process Flow and Production Equipment

1. Liaoning Chuangshi Molybdenum Industry (Group) Co., Ltd. has been committed to the technological innovation and development of molybdenum products since 2011, mainly engaged in the production of molybdenum products, such as industrial molybdenum oixide, high soluble molybdenum trioxide, and ferro-molybdenum, which is an influential medium and large molybdenum industry enterprise in the industry.

2.Liaoning Hongtuo New Material Technology Co., Ltd. mainly aims at the R&D and production of molybdenum deep processing products, and strives to form ‘ammonium molybdate -- high purity molybdenum trioxide -- molybdenum power’ as one of the deep processing industry chain. This project selected automation advanced, technology and environmental protection equipment.

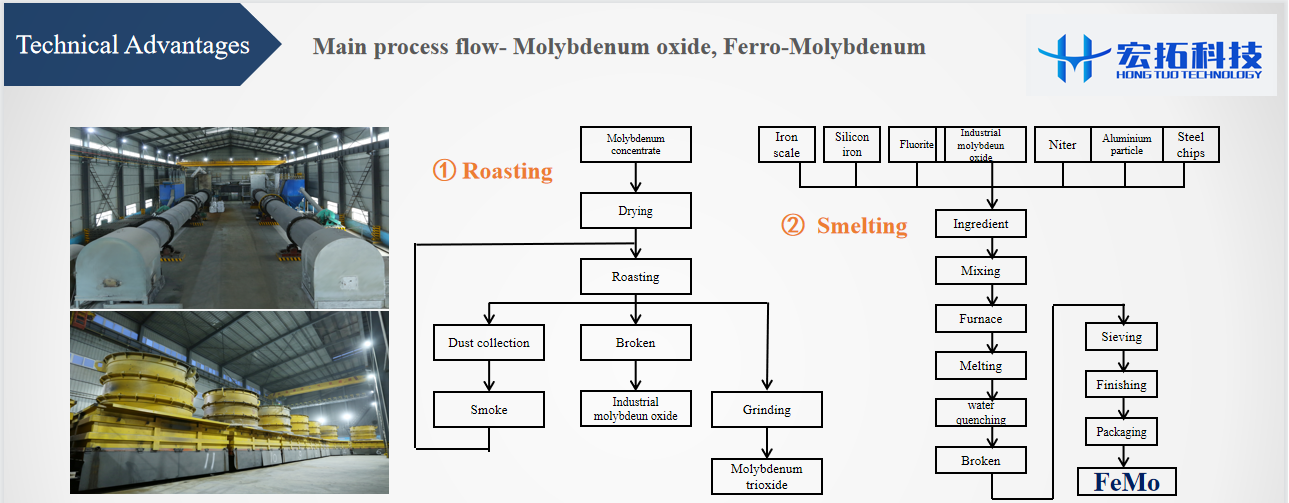

Roasting technology advantages: The first energy- saving rotary kiln molybdenum oxide roasting system is adopted in China. By recycling molybdenum disulfide oxidation reaction, a laqrge amount of heat is released, sufficient and high temperature oxygen supply is maintained, and endergy saving raosting approaching zero enery consumption is realized after normal production of molybdenum oxide. This system cam realized the function of automatic feeding dying, energy saving and roasting and smoke cooling, automatic recycling, and cooling crushing mixture packaging function. This system can greatly reduce prodcution cost. Smelting technology advantages: Ferro-molybdenum smelting using high automation system, the whole smelting process of each smelting furnace independent operation in turn, a high degree of automation, compare with the traditional way of production efficency increased by 100%, workers reduce 100% labor intensity, can realize automatic contunuous production. Smelting Feroo-molybdenum with Si-Al thermal reduction process as the main production process, also known as outside the furnace smelting process. Ferro-molybdenum contains 60%-75% molybdenum, the product is base on block, particle size of 10-100mm. |

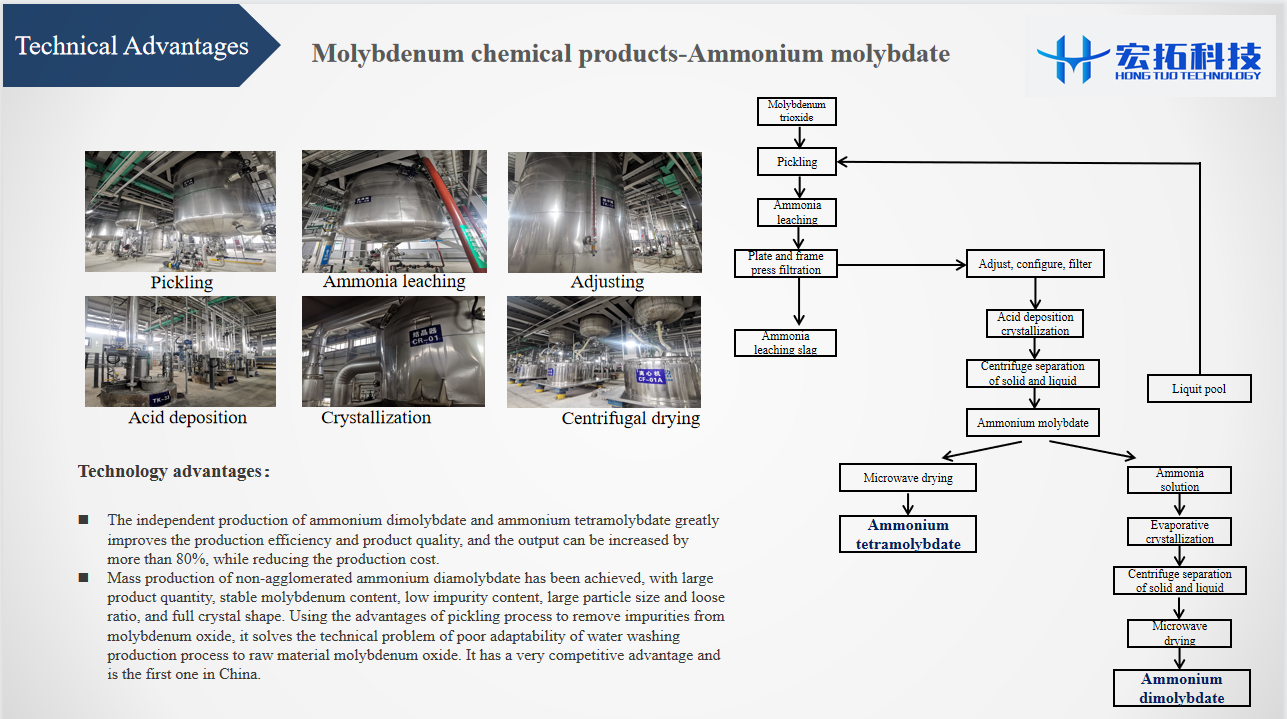

Technology advantages: The independent production of ammonium dimolybdate and ammonium tetramolybdate greatly improves the production efficiency and product quality, and the output can be increased by more than 80%, while reducing the production cost. Mass production of non-agglomerated ammonium diamolybdate has been achieved, with large product quantity, stable molybdenum content, low impurity content, large particle size and loose ratio, and full crystal shape. Using the advantages of pickling process to remove impurities from molybdenum oxide, it soves the technical problem of poor adaptability of water washing production process to raw material molybdenum oxide. It has a very competitive advantage and is the first one in China. |

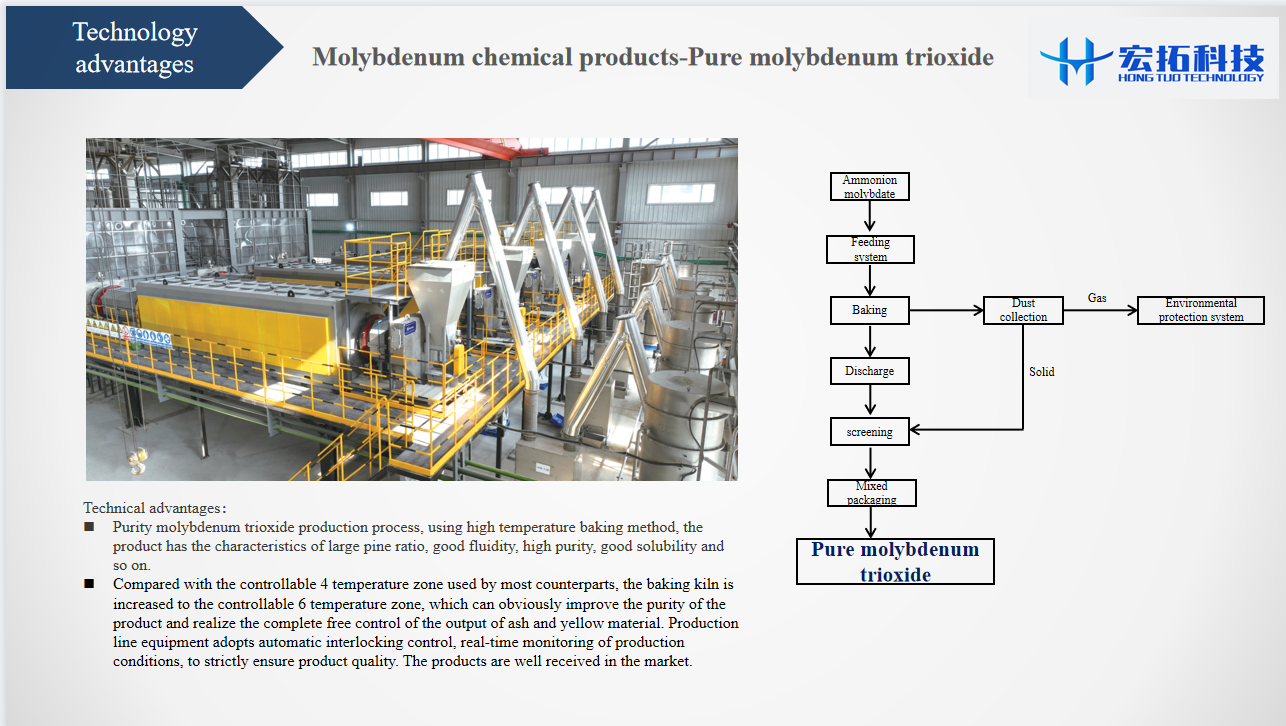

Technical advantages: Purity molybdenum trioxide production process, using high temperature baking method, the product has the characterisitics of large pine ratio, good fluidity, high purity, good solubility and so on. Compared with the controllable 4 temperature zone used by most counterparts, the baking kiln is increased to the controllable 6 temperature zone, which can obviously improve the purity of the product and realize the complete free control of the output of ash and yellow material. Production line equipment adopts automatic interlocking control, real-time monitoring of production conditions, to strictly ensure product quality. The products are well received in the market. |