Ferro Molybdenum(FeMo)

Brand hongtuo

Product origin China

Delivery time 7-15 days

Supply capacity 20000 MT/Year

1. We can provide ferro molybdenum lump in block, granular and powder form to meet the particle size requirements of metallurgy, casting, welding materials and other industries.

2. The ferro molybdenum lump we produce can be customized with different molybdenum content (such as FeMo60, FeMo70, etc.) and particle size distribution according to customer process requirements.

3. We have a supporting chemical analysis and metallographic analysis laboratory. Each batch of ferro molybdenum lump must undergo ICP spectral analysis, carbon and sulfur analysis and other tests before leaving the factory.

Introduction of ferro molybdenum lump:

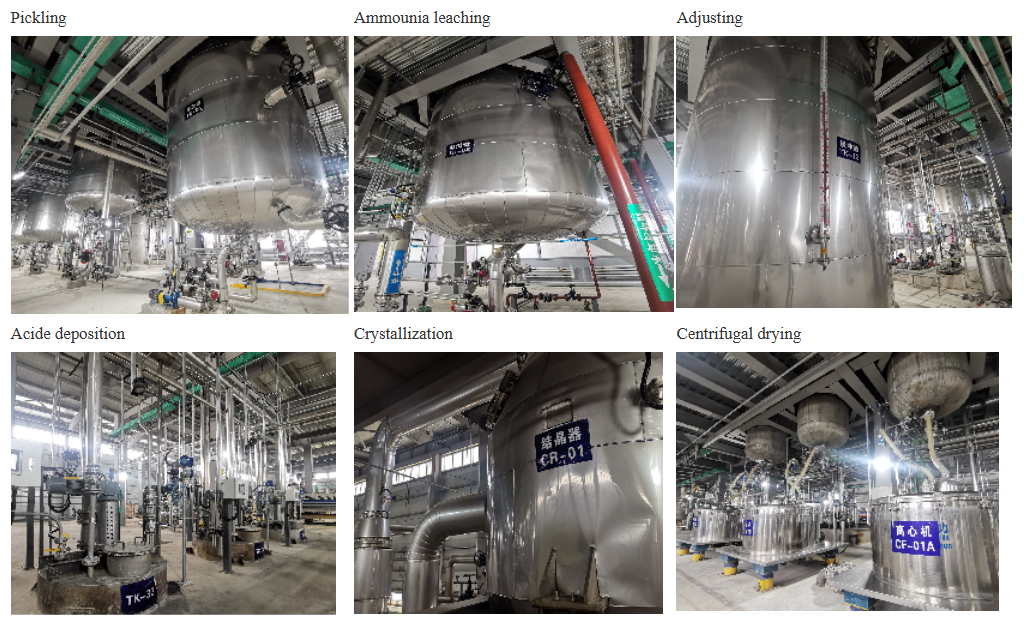

Molybdenum prevents corrosion in stainless steel, and when mixed with iron, ferro molybdenum granules also strengthens and hardens into austenite. Adding molybdenum to iron castings can improve application and wear resistance, and adding ferro molybdenum lump (FeMo) can improve the chemical and physical properties of a variety of steels, such as alloy structural steels, tool steels and high-speed steels, stainless steels, super alloys and cast iron, as well as steel castings. Our company currently has 10 rotary kilns and an annual production capacity of 20,000 tons of ferro molybdenum briquette, with complete upstream and downstream supporting advantages such as ammonium molybdate, molybdenum trioxide, molybdenum powder, ferromolybdenum, and molybdenum metal.

Properties of ferro molybdenum briquettes:

Ferro molybdenum briquettes are additives to the amorphous metal production process. One of the main benefits of adding ferro molybdenum briquettes (Fe-Mo) to alloys is its hardening properties. Ferro molybdenum briquettes also make steel very strong and weldable, as molybdenum is one of the top 5 melting point metals. Additionally, adding ferro molybdenum chunks (Fe-MO) to alloys can increase corrosion resistance. The properties of ferro molybdenum chunks make them suitable for a variety of protective films on other metals.

Functions and applications of ferro molybdenum chunks (Fe-Mo):

The biggest practical application of ferro molybdenum chunks (Fe-MO) is its use in ferrous alloys, depending on the molybdenum content range, ferro molybdenum chunks are suitable for machine tools and equipment, military hardware, refineries, refinery pipes, load-bearing parts, and rotary drilling rigs. Ferro molybdenum lump is also used in cars, trucks, locomotives, and boats. Besides, ferro molybdenum chunk is used by synthetic fuel and chemical plants, heat exchangers, generators, frying equipment, pumps, turbine pipes, ships.

Parameters of ferro molybdenum granules:

| Brand | Chemical element composition (Chemical Contents)% | |||||||

| Mo (Min) | Si | S | P | C | Cu | Sb | Sn | |

| MAX | ||||||||

| FeMo70 | 65.0-75.0 | 2.0 | 0.08 | 0.05 | 0.1 | 0.5 | - | - |

| FeMo60-A | 60.0-65.0 | 1.0 | 0.08 | 0.04 | 0.1 | 0.5 | 0.04 | 0.04 |

| FeMo60-B | 60.0-65.0 | 1.5 | 0.1 | 0.05 | 0.1 | 0.5 | 0.05 | 0.06 |

| FeMo60-C | 60.0-65.0 | 2.0 | 0.15 | 0.05 | 0.15 | 1.0 | 0.08 | 0.08 |

| FeMo55-A | 55.0-60.0 | 1.0 | 0.1 | 0.08 | 0.15 | 0.5 | 0.05 | 0.06 |

| FeMo55-B | 55.0-60.0 | 1.5 | 0.15 | 0.1 | 0.2 | 0.5 | 0.08 | 0.08 |

Why choose ferro molybdenum lump from Hongtuo?

1. Our ferro molybdenum granules are produced using high-grade molybdenum concentrate and refined by vacuum smelting and late filtration, able to reach a molybdenum content between 60%±1%

2. Customizable size and chemical composition of our ferro molybdenum granules according to your furnace or alloy requirements.

3. Each batch is tested by carbon sulfur analyzer and XRF spectrometer, in line with international requirements.

4. From raw material processing to vacuum melting and packaging. ISO certified factory with fully automatic smelting and batch processing system. In addition, ferro molybdenum granules are supplied to more than 20 countries including South Korea, India, Turkey, Germany and Brazil.

About Us

Hongtuo is a Chinese manufacturer specializing in ferro molybdenum granules and alloy additives for the global metallurgical industry. Located in the heart of China's molybdenum resource belt, we combine abundant raw material access, advanced smelting technology and strict quality control systems to provide consistent high purity products to global steel manufacturers.

With more than 10 years of export experience, we support international partners with fast delivery, customized specifications and reliable technical support.