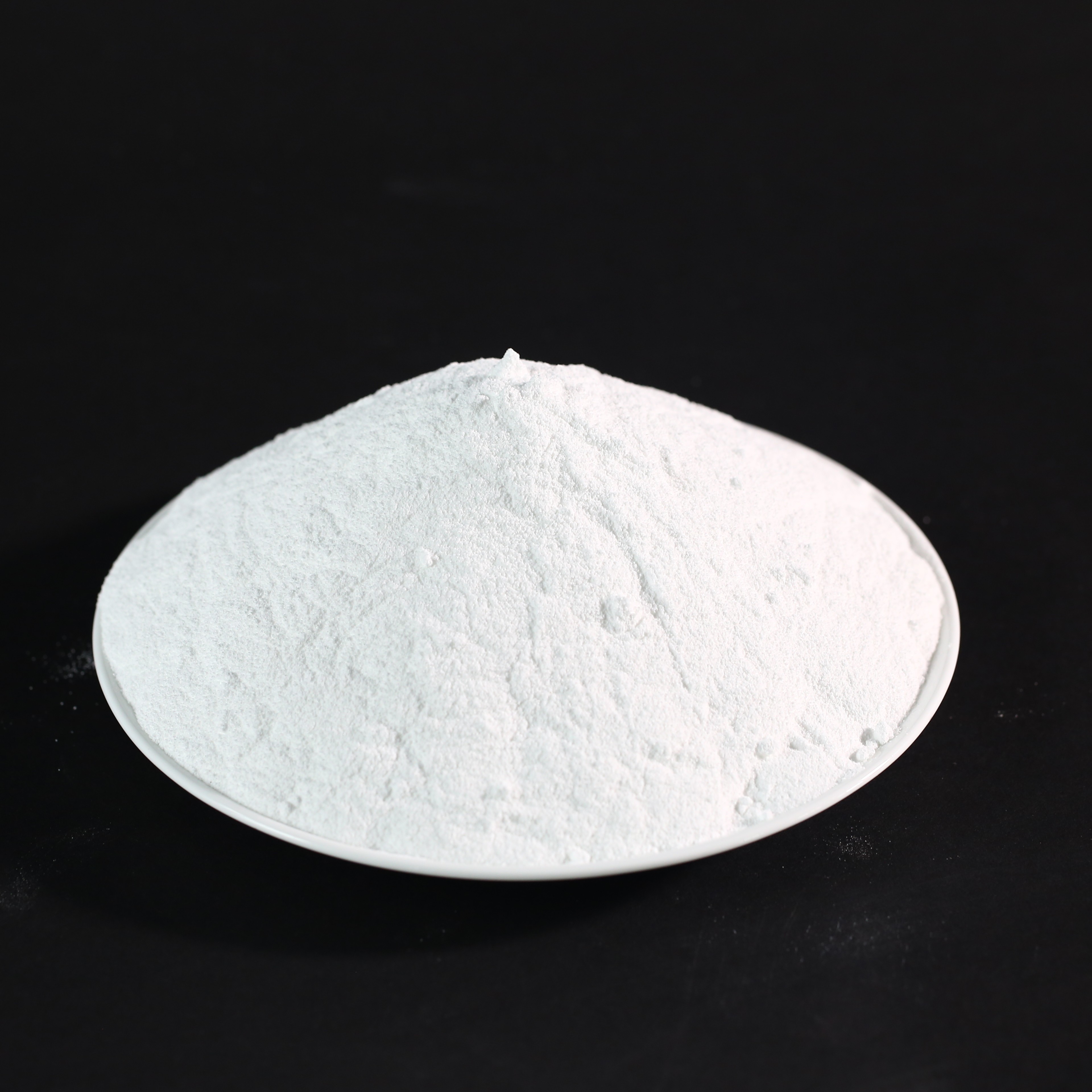

Ammonium Tetramolybdate AQM [(NH4)2Mo4O13·2H2O]

Brand hongtuo

Product origin China

Delivery time 7-15 days

Supply capacity 20000 MT/Year

1. The Mo content of Ammonium tetramolybdate AQM is ≥ 56%, with high crystallinity, uniform particles, strict impurity control, stable reaction efficiency and quality.

2. The powder bulk density (0.60–1.40 g/cm³) and average particle size (10–30 μm) of Ammonium tetramolybdate AQM are suitable for various downstream processes such as roasting and metallurgy.

3. Ammonium tetramolybdate AQM can be widely used in the manufacture of molybdenum red pigments, catalyst carriers, flame retardants, and precision alloy products.

Introduction of ammonium tetramolybdate AQM:

Ammonium tetramolybdate AQM is an intermediate in the molybdenum deep processing industry chain. It has the appearance of high-purity white crystalline powder, soluble in ammonia and alkali, slightly soluble in water, insoluble in alcohol and acetone. The average particle size of ammonium tetramolybdate for petroleum refining is controlled at 10-30 microns, which is suitable for various molybdenum-based catalysts, alloy products, ceramic pigments and agricultural trace element addition and other application scenarios. Ammonium tetramolybdate for petroleum refining is the basic raw material for manufacturing high-performance molybdenum compounds and metal molybdenum products. Ammonium tetramolybdate for petroleum refining widely serves multiple industries such as petrochemicals, agriculture, military industry, ceramic pigments, flame-retardant textile materials, etc.

Why choose our ammonium molybdate AQM?

1. Ammonium molybdate AQM adopts a fully automatic crystallization, drying and packaging system to avoid artificial fluctuations. Each batch of products has stable indicators, no agglomeration, and no impurities, which is suitable for large-scale industrial applications.

2. The full-process laboratory testing system, from raw materials, reaction process, to factory inspection, is strictly controlled. COA is attached to the factory and supports third-party testing.

3. Self-built waste heat recovery roasting system, almost zero energy consumption, the environmental emissions of ammonium tetramolybdate for petroleum refining meet national standards, and the downstream production pressure of customers is smaller, which meets regulatory requirements.

Parameters of ammonium molybdate AQM:

| Name | Ammonium tetra molybdate |

| Other names | Ammonium molybdate AQM |

| CAS number | 13106-76-8 |

| Molecular formula | [(NH4)2Mo4O13·2H2O] |

| Melting point of ammonium tetra molybdate | 170 (decomposition) |

| Purity of ammonium tetra molybdate | Molybdenum>=56% |

| Use | Used in the manufacture of molybdenum rods, molybdenum wires, molybdenum plates, molybdenum rods |

| Appearance | White crystalline powder, no visible impurities |

What is the value of our ammonium molybdate AQM?

1. Our ammonium molybdate AQM can be used to produce molybdenum powder, molybdenum bars, catalyst mother salt, etc., and eventually enter high-profit industries such as military industry, medical, electronics, and petrochemicals.

2. Our ammonium molybdate AQM has high purity, low impurities, high reaction efficiency, can reduce filtration, cleaning, reprocessing losses, and reduce unit energy consumption and labor costs.

3. Ammonium tetra molybdate has less raw material fluctuations and strong processing consistency, which can reduce the defect rate or failure rate of customer terminal products and enhance the overall brand image and order delivery stability.

4. Our ammonium tetra molybdate supports customized particle size, packaging specifications, and component indicators to meet different application requirements such as catalysts, alloys, and pigments.

About us:

Liaoning Hongtuo is a subsidiary of Liaoning Chuangshi Molybdenum Industry (Group) Co., Ltd., registered and established in 2019. The factory is located at No. 52, Zhongxin Road, Taihe District, Jinzhou City, Liaoning Province, China. The factory covers an area of 66,700 square meters, and the first phase has a construction area of 28,500 square meters. It is mainly engaged in the production of molybdenum products such as industrial molybdenum oxide, high-soluble molybdenum trioxide, ferromolybdenum, and deep processing of molybdenum products, including ammonium dimolybdate ADM, ammonium tetra molybdate, pure molybdenum trioxide, molybdenum powder and other molybdenum metal materials, as well as the production and sales of required raw and auxiliary materials.

![Ammonium Tetramolybdate AQM [(NH4)2Mo4O13·2H2O]](https://img.waimaoniu.net/3528/3528-202507270146285309.jpg)