Ammonium Dimolybdate ADM

Brand hongtuo

Product origin China

Delivery time 7-15 days

Supply capacity 20000 MT/Year

1. The Mo content of ammonium dimolybdate ADM is ≥56%, the conversion rate of molybdenum trioxide is as high as 84%, and the impurity control accuracy is better than the industry standard.

2. The solubility of ammonium dimolybdate ADM in water is 42g/100ml, which is suitable for a variety of catalysts and molybdenum powder production processes.

3. Metal impurities such as Si, Fe, and Cu are controlled below 5ppm. Ammonium dimolybdate for catalyst is suitable for high-end uses such as electronic grade and precision synthesis.

Introduction of ammonium dimolybdate ADM:

Ammonium dimolybdate ADM (ADM for short) is a high-purity, soluble molybdenum-based intermediate with a molecular formula of (NH₄)₂Mo₂O₇. The appearance of ammonium dimolybdate ADM is a white loose crystalline powder with good water solubility and thermal stability. Ammonium dimolybdate ADM is a key raw material for the preparation of high-purity molybdenum trioxide, metallic molybdenum and various molybdenum compounds. It is widely used in catalyst manufacturing, electronic materials, agricultural fertilizers and metal smelting.

The ammonium tetramolybdate dihydrate produced by our company adopts an independent acid washing and purification process to effectively reduce the impurity content (such as silicon, iron, aluminum, etc. are controlled within 5ppm). The purity of ammonium tetramolybdate dihydrate is ≥99.5%, and the molybdenum content is as high as 56%. Ammonium dimolybdate powder has the characteristics of strong solubility, extremely low impurities and good batch stability.

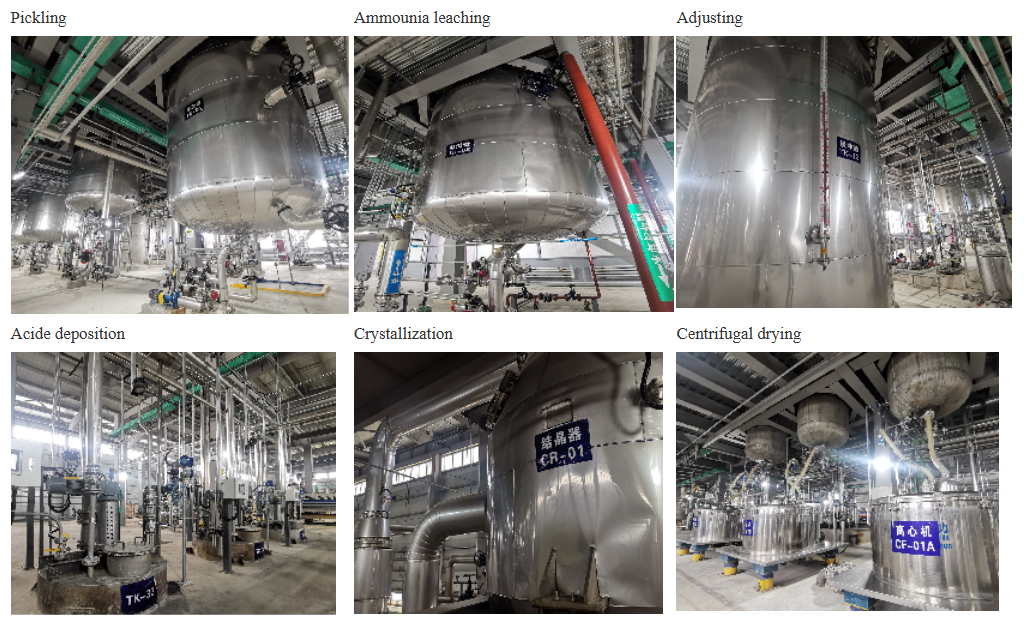

Production workshop of ammonium tetramolybdate dihydrate:

Hongtuo New Materials adopts full-process automated equipment, with standardized workshop layout and visualized operation process, and each process is efficient, stable and safe. The workshop is equipped with high-standard equipment such as pickling and refining system, reaction crystallization equipment, centrifugal drying system, automatic packaging system, etc. The key control links are accurately monitored by intelligent systems to improve the purity and production efficiency of ammonium dimolybdate.

Core process display:

1. Pickling and refining → crystallization reaction → centrifugal dehydration → low-temperature drying → automatic packaging.

2. Fully enclosed dust-free management to effectively prevent secondary contamination of impurities.

3. The annual output of ammonium tetramolybdate dihydrate exceeds 12,000 tons, and we can deliver in batches and provide stable supply.

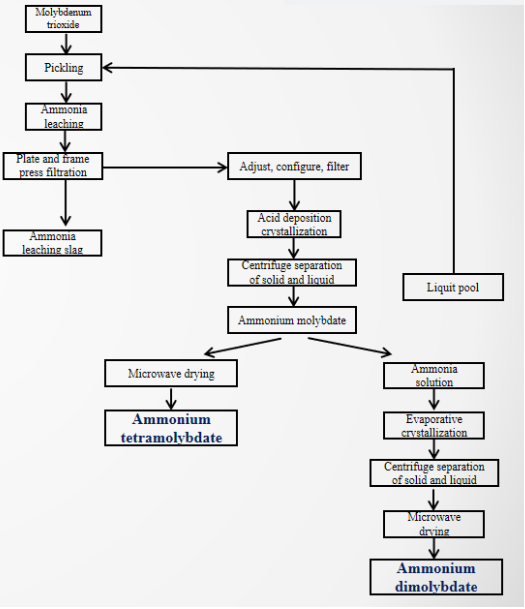

Process flow of ammonium tetramolybdate dihydrate:

Pickling → Filtration → Neutralization → Crystallization → Centrifugal drying → Packaging and storage.

↓ ↓

Molybdenum trioxide roasting → Molybdenum powder reduction → Pure molybdenum material processing.

↓

Customized product output.

Parameters of ammonium dimolybdate for catalyst:

| Product name | Ammonium dimolybdate for catalyst |

| CAS number | 27546-07-2 |

| Purity | 99.5% minimum |

| Classification | Other inorganic salts |

| MF | (NH4)2Mo2O7 |

| Grade standard | Agricultural grade, electronic grade, industrial grade |

| Appearance | White crystal |

| Application | Molybdenum powder raw material |

| Color | White |

| Solubility | Soluble |

| Main content (%) ≥ | 99 | |

| Molybdenum (%) ≥ | 56.00 (Molybdenum trioxide 84%) | |

| Other elements content (%) ≤ | Silicon | 0.0005 |

| Aluminum | 0.0005 | |

| Iron | 0.0005 | |

| Copper | 0.0003 | |

| Magnesium | 0.0005 | |

| Manganese | 0.0003 | |

| Nickel | 0.0003 | |

| Phosphorus | 0.0005 | |

| Potassium | 0.01 | |

| Sodium | 0.0006 | |

| Calcium | 0.0006 | |

| Lead | 0.0005 | |

| Tin | 0.0005 | |

Physical and chemical properties of ammonium dimolybdate for catalyst:

White powder, easily soluble in water and alkali, insoluble in alcohol and acetone. The solubility in water at 25℃ (77℉) is 42g/100ml.

Packing and delivery method of ammonium dimolybdate powder:

Packing specifications of ammonium dimolybdate powder: 25kg / 50kg woven bag, 25kg cardboard drum, 50kg iron drum.

Packing process of ammonium dimolybdate powder: double-layer moisture-proof inner bag + reinforced outer bag / iron drum. Support customized packaging and labeling.

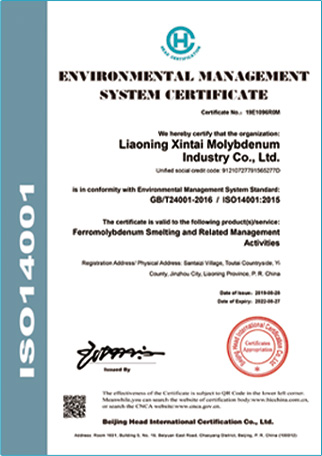

Certification of ammonium dimolybdate powder:

The company has multiple certifications (ISO9001, ISO14001, ISO45001, etc.

Certification

Certification